- IT solutions are essential in 2025 for streamlining manufacturing operations, improving productivity, and staying competitive.

- ERP and MES systems provide centralized data and real-time shop-floor visibility, reducing inefficiencies across the supply chain.

- Emerging technologies like AI, IIoT, and digital twins enable predictive maintenance, smarter decision-making, and innovation at lower risk.

- Cloud-based and cybersecurity solutions ensure scalability, flexibility, and protection of sensitive manufacturing data.

- Robotics and automation drive efficiency, safety, and cost savings while supporting customized production.

- Entrepreneurs must evaluate scalability, ROI, and security when selecting IT solutions to ensure long-term benefits.

The manufacturing industry has always been at the heart of economic growth and innovation. But in 2025, the game has changed significantly. With growing competition, shifting supply chains, and increasing demands for quality and sustainability, manufacturers cannot rely on traditional practices alone. Entrepreneurs in this space must explore the latest IT solutions to streamline operations, reduce costs, and enhance productivity. From automation to cloud-based systems, technology is no longer optional—it’s the foundation for staying competitive.

This article explores the top IT solutions for the manufacturing industry in 2025, breaking down their applications, benefits, and how entrepreneurs can strategically implement them to gain an edge.

Why Are IT Solutions Crucial for the Manufacturing Industry in 2025?

The manufacturing industry has entered an era where agility, precision, and speed are critical. With global supply chains becoming more complex and consumer demand for customization increasing, businesses face mounting pressure. Entrepreneurs cannot afford inefficiencies, as even small errors can disrupt production or erode profit margins. IT solutions offer the means to address these challenges directly.

Through digital transformation, manufacturers can harness real-time data, automate repetitive processes, and achieve levels of visibility that were once unimaginable. From predictive maintenance that prevents costly downtime to enterprise systems that connect every department, IT solutions redefine how companies operate. In 2025, those who fail to adapt risk being left behind by competitors who embrace technology as a core business strategy.

What Are the Top IT Solutions for the Manufacturing Industry in 2025?

Technology has expanded so rapidly that manufacturers now have access to an ecosystem of IT solutions tailored to their needs. Below are the top innovations entrepreneurs should explore in 2025.

1. Enterprise Resource Planning (ERP) Systems

Enterprise Resource Planning (ERP) systems remain a cornerstone of manufacturing efficiency. These centralized platforms integrate business functions such as finance, supply chain, procurement, and production into one system. For entrepreneurs, ERP eliminates silos, providing better visibility and coordination across departments.

Benefits of ERP Systems for Manufacturing:

- Centralized data management for improved decision-making.

- Enhanced supply chain tracking from raw materials to delivery.

- Streamlined procurement and inventory management.

- Real-time reporting to monitor productivity and costs.

- Improved compliance with regulations through better record-keeping.

Modern ERP systems in 2025 also leverage AI and predictive analytics, giving entrepreneurs the ability to forecast demand, optimize resources, and prevent waste.

2. Manufacturing Execution Systems (MES)

While ERP handles high-level planning, Manufacturing Execution Systems (MES) focus on shop-floor operations. MES bridges the gap between planning and production, ensuring workflows are optimized in real time.

Key Advantages of MES:

- Real-time monitoring of production lines.

- Immediate identification of bottlenecks or quality issues.

- Seamless integration with IoT devices and machinery.

- Enhanced traceability for each step in the production process.

- Better resource allocation based on current workloads.

By adopting MES, entrepreneurs can create smarter, more agile factories that adapt instantly to changes in demand or unexpected disruptions.

3. Industrial Internet of Things (IIoT)

The Industrial Internet of Things (IIoT) is revolutionizing manufacturing in 2025. By connecting machines, devices, and systems via sensors and smart technology, IIoT enables factories to become fully data-driven.

Applications of IIoT in Manufacturing:

- Predictive maintenance: detecting issues before equipment fails.

- Energy management: reducing waste and optimizing power usage.

- Supply chain visibility: tracking materials in transit.

- Quality assurance: monitoring product specifications during production.

- Worker safety: ensuring compliance through wearable IoT devices.

For entrepreneurs, IIoT translates into reduced downtime, higher productivity, and more sustainable operations—critical factors for success in today’s competitive landscape.

4. Artificial Intelligence and Machine Learning

Artificial Intelligence (AI) and Machine Learning (ML) are no longer futuristic concepts—they’re vital tools for manufacturing in 2025. Entrepreneurs can leverage AI to analyze massive amounts of data and uncover insights that improve efficiency.

How AI and ML Support Manufacturers:

- Predictive demand forecasting to reduce overproduction.

- Automated quality inspections using computer vision.

- Optimized supply chain routes for faster deliveries.

- Smart robotics that adapt to new tasks without reprogramming.

- Dynamic scheduling for workers and machines.

With AI, manufacturers not only improve performance but also gain the ability to innovate faster, creating custom solutions that meet evolving customer needs.

5. Cloud-Based IT Solutions for Manufacturing Industry

Cloud technology is transforming how manufacturers access and manage their IT systems. By moving to the cloud, entrepreneurs gain scalability, flexibility, and cost savings while reducing reliance on physical infrastructure.

Benefits of Cloud Solutions in Manufacturing:

- Remote access for managing operations across locations.

- Lower upfront costs compared to traditional IT infrastructure.

- Enhanced collaboration between global teams and suppliers.

- Real-time data synchronization across departments.

- Increased security and disaster recovery capabilities.

In 2025, hybrid cloud models—where companies use both private and public clouds—are especially popular among manufacturers that need control, security, and scalability.

6. Cybersecurity Solutions

As manufacturers embrace digital tools, cyber threats pose increasing risks. Entrepreneurs must prioritize cybersecurity solutions to protect intellectual property, sensitive data, and supply chain systems.

Core Cybersecurity Measures for Manufacturing:

- Multi-factor authentication and access controls.

- Encryption for sensitive data transfers.

- Real-time threat detection systems.

- Regular vulnerability assessments.

- Employee training on cybersecurity best practices.

Cyberattacks can cripple manufacturing operations, leading to downtime, financial losses, and reputational damage. Robust cybersecurity is no longer optional—it’s mission-critical.

7. Robotics and Automation

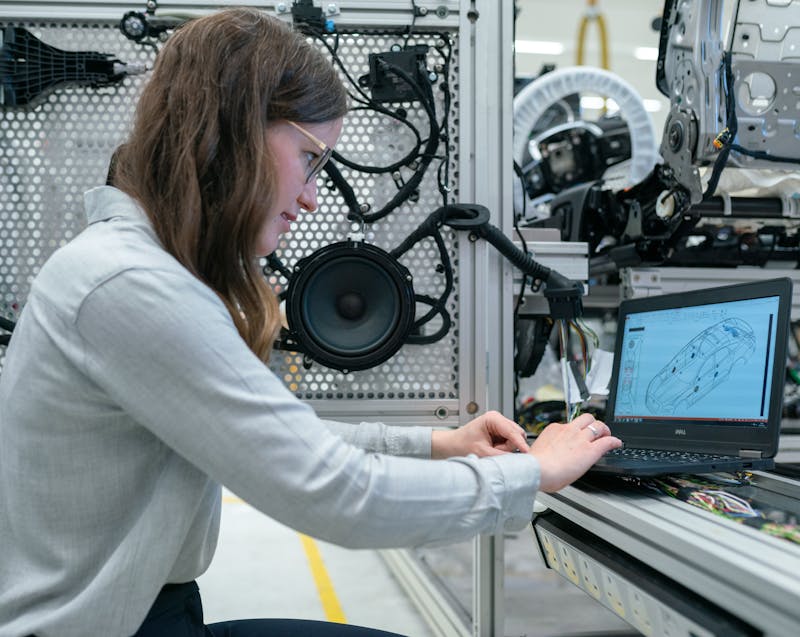

Automation has long been part of manufacturing, but in 2025, robotics has reached a new level. From collaborative robots (cobots) to fully autonomous systems, entrepreneurs can harness robotics to boost efficiency while reducing reliance on manual labor.

Advantages of Robotics in Manufacturing:

- Precision and consistency in repetitive tasks.

- Increased safety by handling hazardous processes.

- Round-the-clock productivity with minimal downtime.

- Lower operational costs over the long term.

- Flexibility to adapt to customized production runs.

Robotics, paired with AI, allows for adaptive learning—machines that can adjust operations without human intervention, driving even greater productivity.

8. Advanced Analytics and Big Data

Manufacturing generates enormous amounts of data daily, from machine performance to customer orders. Advanced analytics and big data solutions help entrepreneurs transform raw information into actionable insights.

Uses of Big Data in Manufacturing:

- Identifying inefficiencies in the production line.

- Forecasting demand with greater accuracy.

- Optimizing supply chain logistics.

- Enhancing customer experience through data-driven product improvements.

- Supporting sustainability goals by analyzing resource usage.

By integrating analytics into decision-making, entrepreneurs can future-proof their operations and gain a competitive edge.

9. Digital Twin Technology

Digital twin technology creates a virtual replica of a physical product, system, or process. For manufacturers, this innovation offers immense opportunities to test and optimize without disrupting real-world operations.

Benefits of Digital Twins in Manufacturing:

- Simulation of new product designs before production.

- Real-time monitoring of equipment performance.

- Predictive maintenance to extend asset life.

- Better collaboration between design and engineering teams.

- Reduced costs by identifying issues virtually.

Entrepreneurs using digital twins can experiment with new ideas at lower risk while ensuring efficiency in real-world production.

10. Supply Chain Management Software

Global supply chains are more complex than ever, with disruptions often affecting production. Advanced supply chain management (SCM) software enables entrepreneurs to maintain resilience and adaptability.

Features of SCM Software:

- Real-time visibility of shipments and inventory.

- Automated procurement and order management.

- Risk analysis for identifying potential bottlenecks.

- Enhanced collaboration with suppliers and distributors.

- Integration with ERP and MES systems.

In 2025, SCM software is powered by AI and blockchain, ensuring transparency and reliability in even the most complex supply chains.

How Can Entrepreneurs Choose the Right IT Solutions?

With so many IT solutions available, entrepreneurs must make strategic choices to ensure alignment with their business goals.

Tips for Selecting IT Solutions:

- Define Objectives: Clarify whether the goal is cost reduction, productivity improvement, or quality enhancement.

- Assess Scalability: Ensure the solution can grow with the business.

- Evaluate ROI: Consider both short-term costs and long-term savings.

- Check Compatibility: Look for systems that integrate easily with existing platforms.

- Prioritize Security: Never compromise on cybersecurity features.

- Consult Experts: Work with IT consultants or vendors specializing in manufacturing.

Careful evaluation ensures that investments in technology yield measurable benefits.

What Challenges Do Manufacturers Face When Implementing IT Solutions?

While IT solutions offer undeniable advantages, implementation is not without challenges. Entrepreneurs must be prepared to address these hurdles:

- High Initial Costs: Though long-term savings are significant, upfront investments can be substantial.

- Resistance to Change: Employees may hesitate to adopt new systems or processes.

- Integration Issues: Legacy systems may not easily connect with modern IT solutions.

- Cybersecurity Risks: New technologies increase exposure to digital threats.

- Training Needs: Staff must be properly trained to maximize the potential of IT tools.

Overcoming these obstacles requires strong leadership, a clear roadmap, and ongoing support from IT experts.

The Future of IT Solutions in the Manufacturing Industry

Looking ahead, IT solutions will continue to evolve, offering even more advanced tools for manufacturers. Emerging trends such as edge computing, blockchain, and 5G connectivity will expand the possibilities for smart factories. Entrepreneurs who adopt early will not only streamline operations but also position themselves as industry leaders.

The future of manufacturing will be defined by agility, sustainability, and innovation. IT solutions are the bridge that helps entrepreneurs move from traditional models to forward-thinking, resilient businesses ready for global challenges.

Conclusion

The manufacturing industry in 2025 demands speed, precision, and adaptability. Entrepreneurs who embrace IT solutions gain the ability to streamline operations, reduce costs, and stay ahead of competitors. From ERP and MES systems to AI, robotics, and digital twins, these technologies are no longer optional—they are essential for survival and growth.

By carefully selecting and implementing the right IT solutions, manufacturers can transform their businesses into future-ready enterprises. The message is clear: in 2025, IT isn’t just supporting manufacturing—it’s driving it.